A fuse circuit breaker switch enhances safety by combining a fuse and a breaker in one unit. This combination offers robust short circuit protection. If an issue arises, the fuse circuit breaker switch promptly disconnects the circuit, preventing overheating, reducing fire hazards, and safeguarding your devices. The inclusion of the fuse provides an additional layer of safety, making these breakers ideal for protecting electrical systems.

Key Takeaways

-

Fused breakers have both a fuse and a breaker for safety.

-

They act quickly during high currents, stopping fires and damage.

-

Keeping fused breakers in good shape is important for safety.

-

They cost more at first but save money by avoiding repairs.

-

Use fused breakers in factories or places where safety matters most.

Fuse Circuit Breaker Switch: How It Works

The Role of the Fuse in Circuit Breakers

The fuse in a fused circuit breaker switch improves safety. It stops electricity flow when the current gets too high. This prevents overheating, which can cause fires or harm devices. Unlike regular breakers, the fuse adds extra protection by acting quickly in dangerous situations.

Fuses work based on specific tripping patterns. These patterns decide how fast the fuse reacts to different current levels. For example, a big power surge makes the fuse act instantly. A smaller overload might cause a slower reaction. This design protects your system without unnecessary shutdowns. Regular checks and maintenance keep the fuse working properly over time.

Tip: Keep records of maintenance for your fused disconnect switch. This helps meet safety rules and ensures smooth operation.

Mechanisms of a Fused Circuit Breaker

A fused circuit breaker uses both mechanical and electrical parts to protect systems. Its mechanical parts control, carry, and stop current during normal and overload conditions. When a problem happens, the fuse quickly cuts off the circuit to prevent damage.

Here’s a simple look at how fused circuit breakers work:

|

Specification/Metric |

Description |

|---|---|

|

Handles current under normal and overload conditions. |

|

|

Instantaneous Disconnection |

Breaks the circuit instantly with help from the fuse. |

|

Transient Recovery Voltage (TRV) |

Voltage that rises quickly when the circuit is restored. |

|

Contact Separation Rate |

Must be fast enough to handle high TRV safely. |

These features ensure the fused circuit breaker works well in all conditions. The mix of mechanical and electrical parts makes it a dependable choice for protecting systems.

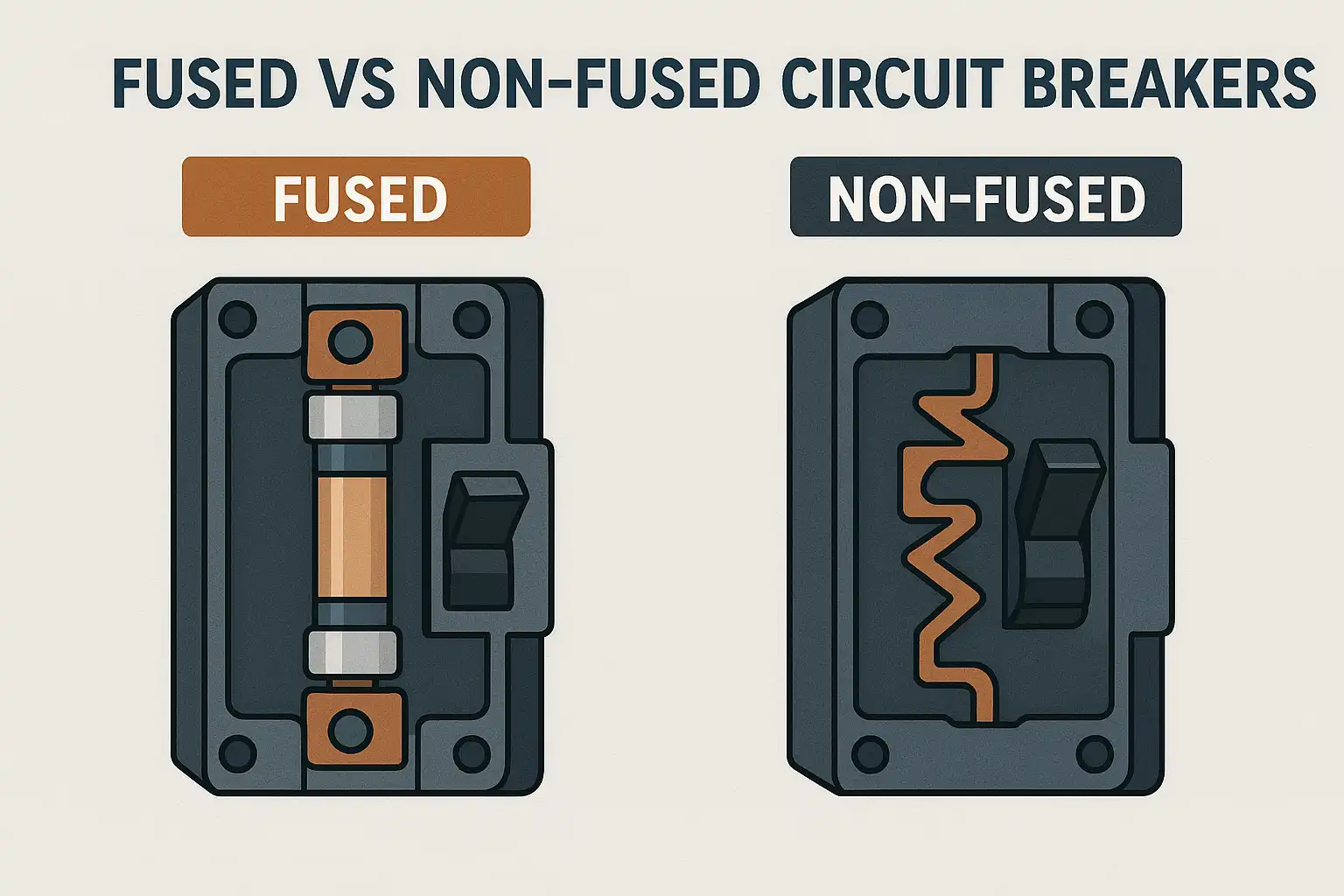

Advantages of Fused Circuit Breakers in Safety

Fused circuit breakers are safer than non-fused ones for several reasons. First, the fuse acts as a backup. If the breaker doesn’t trip, the fuse will still stop the circuit. This reduces the chance of fires or equipment damage.

Second, fused circuit breakers respond faster than non-fused switches. The fuse reacts almost instantly to high fault currents. This quick action is crucial for protecting sensitive equipment or important operations.

Lastly, fused circuit breakers handle tough conditions better. They can stop fault currents and manage high recovery voltages. This makes them great for industrial and commercial use. Choosing a fused disconnect switch means prioritizing safety and reliability, even in hard situations.

Note: Fused circuit breakers may cost more upfront, but their safety and reliability make them worth it in the long run.

Difference Between Circuit Breaker and Fuse: Key Comparisons

Overload and Short-Circuit Protection

Fuses and circuit breakers handle overcurrent differently. Fuses stop short circuits very fast, in under 4 milliseconds. This quick action protects your electrical system from damage. Circuit breakers focus more on stopping overloads. They may not always handle short circuits as well.

Here’s a simple comparison:

|

Feature |

Fuses |

Circuit Breakers |

|---|---|---|

|

Short-Circuit Protection |

Stops faults quickly (under 4 ms) |

May not stop short circuits |

|

Overload Protection |

Slower response (seconds to minutes) |

Designed mainly for overloads |

|

Protection Capabilities |

Handles both short circuits and overloads |

Some models lack short-circuit protection |

Fused disconnect switches combine the best of both. They protect against overloads and short circuits, making them safer for areas with frequent electrical issues.

Tip: Use fused disconnect switches to protect sensitive equipment from damage.

Reusability and Maintenance

How reusable a device is affects how you maintain it. Circuit breakers can be reset after tripping, so they’re easier to use long-term. Fuses must be replaced every time they blow, which takes more time and effort.

Here’s what to know about maintaining these devices:

-

Circuit breakers are simple to maintain. You can test and reset them without replacing parts.

-

Fuses need replacing after each fault. This adds time and cost to maintenance.

-

Fused disconnect switches combine both systems, offering better reliability but needing fuse replacements.

If you want easy maintenance, non-fused switches might seem better. But fused disconnect switches give stronger overcurrent protection, making them worth the extra work.

Response Time and Fail-Safe Features

Response time is key to keeping electrical systems safe. Fuses act fast, opening circuits in 0.05 to 2 seconds during high faults. This speed is great for loads like lights. Circuit breakers are slower but have fail-safe features to trip reliably during overloads.

Here’s a look at response times:

|

Device Type |

Response Time |

|---|---|

|

TVS Diodes |

~1 ps |

|

MOV |

~1 ns |

|

Avalanche/Zener Diode |

<1 µs |

|

GDT |

<5 µs |

Fast fuses in fused disconnect switches react quickly to faults, protecting equipment. For inductive loads, choose fuses with higher ratings to avoid false trips. Non-fused switches are simpler but lack precise and reliable safety features.

Note: Always pick the right fuse rating for your system to stay safe and efficient.

Fused vs Non-Fused Circuit Breakers: Practical Applications

When to Use Fused Circuit Breakers

Fused circuit breakers are great for places needing high safety. They work well in systems with strong fault currents or delicate equipment. The fuse reacts fast to overcurrent, stopping damage and lowering fire risks. Factories with big machines often use fused switches to handle high power and keep things running smoothly.

The NFPA 70 National Electrical Code (NEC) says fused circuit breakers are key for emergency systems. They shut down only the problem area during faults. This is important for hospitals, data centers, and other places where downtime is serious.

Tip: Check and replace fuses often to keep fused switches safe and working well.

Ideal Scenarios for Non-Fused Circuit Breakers

Non-fused circuit breakers are better when saving money and ease matter most. They’re good for homes or small businesses. You can reset them after a fault instead of replacing parts. This makes them handy for systems with fewer fault risks.

Non-fused switches are also useful where maintenance is hard to do often. They cost less over time and are simple to use. They’re perfect for protecting lights or small devices in easy setups.

Note: Non-fused switches are cheaper but don’t protect as well in risky situations.

Industry-Specific Use Cases

Different jobs need different circuit protection. Here’s how fused and non-fused switches work in various places:

|

Application Scenario |

Fused Disconnect Switches |

Non-Fused Disconnect Switches |

|---|---|---|

|

Industrial Field |

Handles strong fault currents safely |

Not ideal for tough conditions |

|

Residential or Small Equipment |

Too much for basic setups |

Affordable and simple to install |

|

Critical Infrastructure |

Keeps systems running during faults |

May not meet strict safety needs |

For motors, fused switches are better than regular fuses. They adjust overload protection and react faster to short circuits. This makes them great for factories with complex systems. Non-fused switches work better for simpler setups with fewer safety needs.

Callout: Pick the right breaker for your job. It keeps systems safe, reliable, and cost-effective.

Maintenance and Cost Considerations

Maintenance Needs of Fused Circuit Breakers

Fused circuit breakers need regular care to work well. Check the fuse often for damage or wear. Replace any blown fuses to keep your system safe. The breaker’s mechanical parts also need testing over time to ensure they handle faults properly.

A fused disconnect switch combines a fuse and breaker but needs more upkeep. Plan regular checks to clean and test its parts. This helps avoid problems like rust or part failures. Keeping a maintenance log is useful. It tracks the switch’s condition and ensures it meets safety rules.

Tip: Use the right fuse rating to avoid extra replacements and keep things running smoothly.

Maintenance Needs of Non-Fused Circuit Breakers

Non-fused circuit breakers are easier to maintain. They don’t use fuses, so there’s no need for replacements. After a fault, you can reset them quickly. Still, regular testing is important to check if the trip mechanism works.

Many places follow an Electrical Maintenance Program (EMP) for upkeep. The table below shows key tasks for non-fused circuit breakers:

|

Requirement |

Description |

|---|---|

|

Electrical Maintenance Program (EMP) |

Create an EMP with clear maintenance steps. |

|

Maintenance Intervals |

Follow NFPA 70B guidelines for how often to check. |

|

Condition Assessments |

Use assessments to decide testing and maintenance schedules. |

Following these steps helps non-fused circuit breakers last longer and lowers the chance of failures.

Cost Implications: Initial vs. Long-Term Investment

Fused circuit breakers cost more upfront because of their design and extra parts. But they offer better protection, saving money by preventing equipment damage. Over time, this makes them a smart investment.

Non-fused circuit breakers are cheaper at first. They don’t have fuses, so they’re simpler and cost less. They also cost less to run since they don’t need consumable parts. The table below compares costs:

|

Cost Type |

Fused Circuit Breakers |

Non-Fused Circuit Breakers |

|---|---|---|

|

Higher due to extra parts but offers better safety. |

Lower upfront cost but less protection. |

|

|

Operational Cost |

Saves money by avoiding equipment damage, though maintenance adds costs. |

Cheaper to maintain with no consumable parts. |

Your choice depends on what matters most. If safety is key, fused switches are worth it. For simpler setups, non-fused breakers are a budget-friendly option.

Fused disconnect switches are safer because they use both a fuse and a circuit breaker. This gives two layers of protection to stop fires and protect devices. Non-fused circuit breakers might cost less at first, but fused ones last longer and work better in places where safety is important. Knowing how these systems differ helps you pick the best one for your setup.

FAQs on fused vs non-fused disconnect switch: Think about your system’s needs before picking a breaker.

FAQ

What is a fused disconnect, and why is it important?

A fused disconnect has a fuse and a switch. It stops power during problems to keep things safe. This is important where strong overcurrent protection is needed.

How does a fused disconnect differ from a non-fused one?

A fused disconnect has a fuse for extra safety. A non-fused one does not. The fuse acts fast to stop faults, making it safer. Non-fused ones are simpler but less safe in risky areas.

Can you reset a fused disconnect after it trips?

No, you can’t reset a fused disconnect. You need to replace the fuse to make it work again. Regular checks help it keep protecting your system.

Where should you use a fused disconnect?

Use a fused disconnect in factories or places with high fault currents. It protects delicate equipment and keeps things safe in tough conditions.

Are fused disconnects more expensive than non-fused ones?

Yes, fused disconnects cost more at first because of their parts. But they save money later by stopping damage and cutting downtime.

The following information may be of interest to you

What are fuses in electrical systems?

What is the difference between a circuit breaker and a fuse?