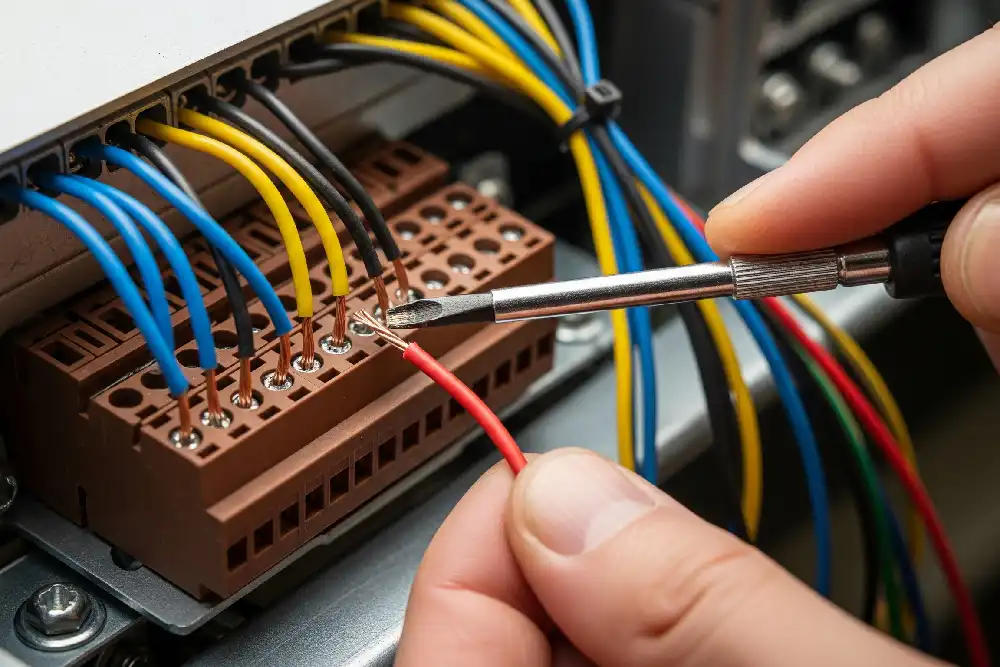

You want to avoid damage when you work with wires in terminal blocks. Use the right tools to keep wires safe and secure. Always handle wires gently and check each connection before you start. If you want to remove wires, look for the release mechanism on the terminal block. Remove the wire from the terminal block with slow and steady movements. You can do this even if you are new to working with wires. Patience and care help you keep wires in good condition.

Key Takeaways

- Always turn off the power first. Use a multimeter to check for safety before you work with terminal blocks.

- Use the right tools like wire strippers, screwdrivers, and special removers. This helps you avoid damage to wires and terminals.

- Find out what type of terminal block you have. This helps you pick the right way and tool to remove wires safely.

- Take out wires slowly and gently. Release clamps or screws without forcing or twisting the wires.

- Check wires and terminals after you remove them. Look for damage and fix or replace parts to keep connections safe and working well.

Tools for Removal

If you want to take wires out of a terminal block, you need the right tools. The correct tools help you remove wires safely and easily. Using them stops damage and keeps your connections working well. You also stay safe if you follow safety rules.

Essential Tools

Get your important tools ready before you start. Here are the main ones you need:

- Wire strippers: These take off the plastic cover from wires. They do not cut the metal inside. Pull-type wire strippers have notches for different wire sizes. You must use them gently so you do not hurt thin wires. Jaw-type wire strippers use two jaws to hold and strip the wire. This makes it safer and more exact.

- Screwdrivers: Use a flathead or Phillips screwdriver to loosen screws on screw-clamp terminals. For spring-clamp terminals, use a small flathead screwdriver or a special spring-clamp tool.

- Multimeter: Always check that the power is off before you touch wires. Use a multimeter to make sure there is no electricity.

- Safety gear: Wear gloves that protect your hands from cuts. Safety glasses keep your eyes safe when you strip big wires or cables.

Tip: Always turn off the power before you start working with a terminal block or take out wires. This keeps you safe from getting shocked.

Optional Tools

Experts use special tools to make removing wires faster and safer. These tools help you work with many kinds of terminal blocks and connectors. The table below shows some popular choices:

| Tool Name | Key Feature/Use Case |

|---|---|

| Terminal Removal Tools – 5559/5557 Connector Remover | Makes pulling out wires easier, Molex real product |

| Extractor for Dynamic 1000 Series | Made for Dynamic 1000 series connectors |

| Extractor for CE01 Series Contacts | Used for CE01 series contacts |

| Han Waterproof Insertion and Remover | Harting real tool for putting in and taking out |

| Extractor for Universal MATE-N-LOK | Used for Universal MATE-N-LOK connectors |

| Universal MATE-N-LOK Remover | Makes pulling out contacts easier |

| Contact Remover for MIL Connector | Special tool for MIL connectors, safe to use |

| XH Connector Remover | Makes pulling out contacts easier |

| VH Connector Remover | JST real product, makes pulling out easier |

| Contact Block Extractor | Used for connectors to pull out contact blocks |

| Extractor for Dynamic D2 Connector Series | TE Connectivity tool for Dynamic D2 connectors |

| D-Sub Connector with Insertion/Remover for Crimping | Tool for crimp contact putting in and taking out |

| EL Connector Remover | Makes pulling out contacts easier |

| Remover for 5051/5045 Connectors | Molex real product, makes pulling out easier |

| Terminal Extractor Jig for QR/P Series | Special jig for taking out terminals |

| Contact Extractor | General tool for taking out contacts |

| Dynamic Connector Extractor for D3000 Series | TE Connectivity tool for D3000 series |

| Dynamic Connector Remover for D5200 Series | TE real product, makes pulling out easier |

| Extractor for Commercial MATE-N-LOK | Makes pulling out contacts easier |

| PH Connector Removal Tools | Special tool for PH connectors |

| CL07 Waterproof Connector Remover | Tool for taking out waterproof connectors |

| Terminal Extractor Jig for 1600 Series | Jig for taking out terminals in 1600 series |

These extra tools make working with terminal blocks and removing wires much easier. They help you finish faster and keep your wires safe.

How to Remove Wires from Terminal Block

Removing wires from a terminal block can seem tricky, but you can do it safely if you follow the correct procedure. Each terminal block type has its own removal process. You need to know which type you have before you start. This helps you use the right tool and avoid damage.

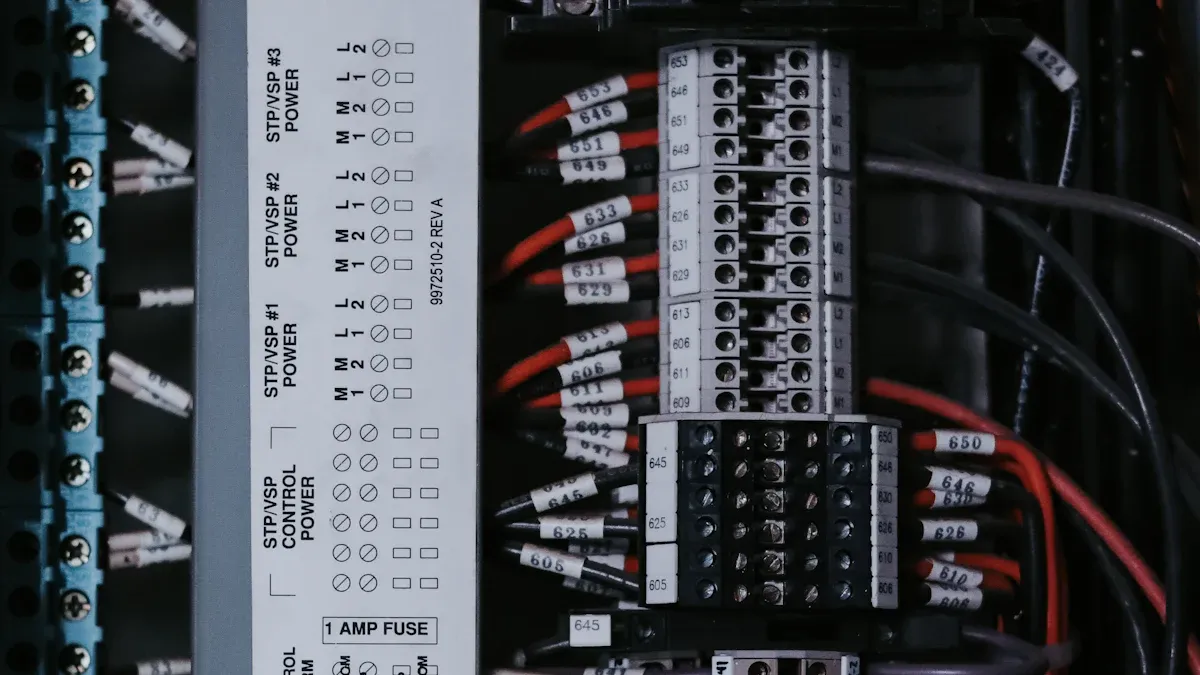

Identify Terminal Block Type

You will find several types of terminal blocks in homes and factories. Each type holds wires in a different way. Here are some common types:

- PCB Mount Terminal Blocks: These connect wires to a printed circuit board. You often see them in electronics.

- Barrier Strips: These use screws to hold ring or spade terminals. They work well where vibration is a problem.

- Feed-Through/DIN Rail Terminal Blocks: These connect two wires together. You often find them on DIN rails in control panels.

- Screw Clamps: These use screws to tighten wires. You see them in many homes and offices.

- Spring Clips: These use a spring to hold wires. They fit well in small spaces.

- Blade Connections: These let you insert or remove wires quickly.

- Fence Terminals: These use screws and help prevent arcing in high-voltage setups.

- Push-In Terminals: These use a spring-loaded lever for easy wire entry.

- Pluggable Terminal Blocks: These let you plug and unplug wires fast.

Tip: Look at your terminal block and match it to one of these types. This helps you choose the right tool and removal method.

Remove the Wire from the Terminal Block

You must use the correct tool and method for your terminal block. Here is a step-by-step guide for the most common types:

For Screw Clamp Terminal Blocks

- Turn off the power and check with a multimeter.

- Use a flathead or Phillips screwdriver.

- Loosen the screw above the wire.

- Gently pull the wire out. Do not twist or yank.

- Tighten the screw after removal if you will not use the terminal.

For Spring-Clamp Terminal Blocks

- Make sure the power is off.

- Find the release slot near the wire entry.

- Use a small flathead screwdriver or a spring-clamp tool.

- Insert the tool into the slot and press to open the spring.

- While holding the spring open, remove the wire from the terminal block with a gentle pull.

- Remove the tool and let the spring close.

For Push-In Terminal Blocks

- Always turn off the power first.

- Use a flathead screwdriver or needle-nose pliers.

- Press the release tab or lever to open the clamp.

- Hold the wire and pull it out slowly.

- If the wire sticks, do not force it. Use gentle pressure or a small amount of lubricant if needed.

For Barrier Strips and Fence Terminals

- Turn off the power.

- Use a screwdriver to loosen the screw.

- Remove the wire from the terminal block.

- Check the wire and terminal for damage.

Note: Always inspect the wire and terminal after removal. If you see any damage, fix it before you reuse the wire.

Release Wires from Terminal Block

You need to release wires from terminal block gently to avoid damage. Each type has a special way to open the clamp or screw.

- Spring terminals have a small arm or tab. Press this with a ball-point pen or screwdriver to open the clamp. This lets you remove the wire from the terminal block without harm.

- For screw terminals, loosen the screw to release the wire. Do not over-loosen, as this can damage the terminal.

- Push-in terminals use a lever or tab. Press it to release wires from terminal block. Pull the wire out slowly.

- Pluggable terminal blocks let you unplug the wire block from the base. This makes removal easy and safe.

Safety Tip: Never use sharp objects or too much force. This can damage the wire or the terminal block. Hold the wire firmly during removal to prevent dropping or bending it.

You lower the risk of wire damage by using the correct procedure and the right tool for each terminal block. Terminal blocks have strong clamping parts and insulated housings. These features keep wires safe and secure. If you match the wire size and amp rating to the terminal block, you also prevent overheating and wire failure.

The removal process works best when you stay patient and gentle. Always check your work after you remove the wire from the terminal block. This keeps your wiring a terminal block project safe and reliable.

Step-by-Step Removal

Preparation

Before you remove the wire from the terminal block, you need to get ready. Good preparation helps you avoid mistakes and keeps your wires safe. Follow these steps to make sure you have everything in place:

- Turn off the power. Always check with a multimeter to confirm that no electricity flows through the wires.

- Check the voltage and current ratings of your terminal block. Make sure they match your wires. This step prevents overheating or electrical failures.

- Inspect each wire. Look for cuts, fraying, or damaged insulation. If you see any problems, fix them before you start.

- Gather all the tools you need. Use the correct screwdriver for screw-type terminal blocks or the right tool for spring-clamp or push-in types.

- Remove any fasteners or covers that hold the terminal block in place.

- If you see a crimped metal lug, use a cutting tool to cut it carefully. Slide off the cut pieces to free the wire.

- After you remove the wire, check it for damage. Trim and re-strip the end if needed. Use a new terminal lug that matches the wire gauge and type.

- For wires with ferrules, make sure the wire is not live. Cut or pinch off the ferrule gently, remove it, and re-strip the wire. Use a new ferrule for re-crimping.

Tip: Proper wire preparation makes the removal process safer and easier. Always double-check your tools and wire condition before you begin.

Loosen or Release Mechanism

Each terminal block type uses a different release mechanism. You need to know how to operate it safely. The table below shows how to identify and use the release mechanism for common terminal block types:

| Terminal Block Type | Release Mechanism | How to Operate Safely | Identification Clues |

|---|---|---|---|

| Screw Terminals | Screws | Use a screwdriver to loosen the screw. Do not over-tighten or over-loosen. Follow the manufacturer's instructions. | Metal or plastic body with visible screws. Common in homes and offices. |

| Spring-Cage (Spring Clamp) Terminals | Spring clamp | Insert a narrow screwdriver into the slot. Press to open the spring. No need for much force. | Spring-loaded clamp visible. Often used for small wires or in places with vibration. |

| Push-In Terminals | Push-fit device | Press the push-fit device or button next to the wire. No tools needed. Follow the instructions for your terminal block. | Push button or tab near the wire entry. Used for fast changes and easy wiring. |

Spring clamp terminal blocks let you open the clamp by inserting a narrow screwdriver into a slot. This method holds wires tightly and resists vibration. Push-in terminal blocks use a push-fit device, so you can release the wire without tools. Always follow the manufacturer’s guidelines for your terminal block. This keeps your connections safe and reliable.

Note: Never force the mechanism. If it feels stuck, check for hidden tabs or locks. Forcing can damage the terminal block or the wire.

Gently Pull Out the Wire

After you release the mechanism, you can remove the wire from the terminal block. Use the correct procedure to avoid damage:

- Identify any locking tabs, side latches, or levers. Release them before you try to pull out the wire.

- Hold the plastic connector housing firmly. Pull straight out along the same direction the wire entered. Do not pull on the wires themselves.

- If the connector feels stuck, use a thin plastic tool to pry gently near the housing seam. Avoid metal tools to prevent scratches or shorts.

- Never use too much force. Pulling hard can pull the crimped terminal out of the housing, which often causes failure.

- Focus your effort near the plastic connector housing, not on the wires or pins. Take your time and use the correct tool placement.

- After you remove wires from terminal block, inspect them for any signs of damage. If you see nicks or bent strands, trim and re-strip the wire before reuse.

Safety Reminder: Patience is key. Rushing this step can damage both the wire and the terminal block. Always use gentle, steady pressure.

By following these steps, you use the correct procedure and keep your wires in good condition. Good removal habits help you avoid common mistakes and keep your electrical projects safe.

Preventing Damage During Removal

Common Mistakes

You may damage wires if you rush or use the wrong tool. Many people pull wires out with too much force. This can break the copper strands or stretch the insulation. Some forget to turn off the power before starting. This mistake can cause electric shock or short circuits. You might use a screwdriver that does not fit the terminal screw. This can strip the screw head or slip and cut the wire. If you do not follow the correct procedure, you risk bending the connector pins or crushing the wire ends.

Other common mistakes include reusing crimped connectors. Most crimped connectors deform permanently and should not be reused. If you skip inspecting wires after removal, you may miss nicks or frays. These small damages can lead to bigger problems later. Over-tightening terminal screws can crack the housing or pinch the wires. If you clean terminals with a wet cloth while the power is on, you risk shorting the wires or damaging the insulation.

Tip: Always slow down and check each step. Careful work keeps your wires safe and your connections strong.

Best Practices

You can protect wires by following a few simple steps. Always turn off the power before you begin. Use a multimeter to confirm that no electricity flows through the wires. Choose the right tool for your terminal block. Match the screwdriver size to the screw head. Use wire strippers that fit your wire gauge.

After removing wires, inspect them closely. Look for nicks, frays, or damaged insulation. If you find damage, trim the wire back to solid copper and strip a new end. Replace crimped connectors with new ones. Only reuse quick-disconnect terminals if they look undamaged. Strip wires to the length recommended by the connector manufacturer. Slide on a new connector and crimp it with the correct tool. If you use heat-shrink tubing, apply heat evenly to seal out moisture.

Check the insulation for cracks or aging. Use an insulation resistance tester if you have one. Tighten terminal screws just enough to hold wires firmly. Clean terminals with a dry brush or alcohol if needed. Keep wires dry and use waterproof covers in damp areas. Test each connection with a gentle tug and check for electrical continuity.

Remember: Careful inspection and proper tools help you avoid damage. Good habits keep your wires working well for a long time.

Troubleshooting Removal Issues

Stuck Wires

You may find that a wire feels stuck in the terminal block. This problem can happen for several reasons. Sometimes, the terminal block uses a ‘single use’ wire hole. These holes do not have a release mechanism. If you try to pull the wire out without knowing this, you may damage the wire or the terminal. In this case, you often need to cut the wire and reattach it using the screw terminal.

Dirt or burrs on the screw threads can also make removal hard. You should check the terminal for any debris. Clean the area with a dry brush or compressed air. If the wire still will not move, check if the wire diameter matches the terminal size. Wires that are too thick or too thin can get stuck. Crimping errors can also cause the wire to jam. If you see this, use a proper crimping tool next time.

Try these steps if you face a stuck wire:

- Double-check for a release tab or lever.

- Gently wiggle the wire while pulling straight out.

- Use a small tool to press the release point, if available.

- If the wire does not move, cut it close to the terminal and prepare a new end.

Note: Never force a stuck wire. Forcing can break the terminal or the wire.

Damaged Wires

You may notice damage after removing a wire. Look for broken strands, nicks, or melted insulation. Damaged wires can cause poor connections or even short circuits. If you see any damage, trim the wire back to clean copper. Strip a fresh end and use a new connector. Never reuse a damaged crimp or terminal.

Sometimes, you find that the terminal block itself is damaged. Loose screws, bent contacts, or cracked housings can make it unsafe. Replace the terminal block if you see these problems. Always test the wire and terminal before you attach wire from battery terminal or other sources.

Tip: Careful inspection after removal helps you catch problems early. Safe wiring starts with good habits.

You can take wires out of terminal blocks if you follow steps. First, turn off the power and get your tools ready. Find out what kind of terminal block you have. Use the right way to release the wire. Pull the wire out slowly and check for any damage. Write down what you do to keep track. Make maps of where the cables go and put labels on wires as you remove them. Update your notes when you finish the job. Work slowly and carefully to keep yourself and your equipment safe. If you have trouble, ask an expert for help.

FAQ

How do you know which tool to use for your terminal block?

You can check the terminal block type first. Look for screws, levers, or push buttons. Use a screwdriver for screw terminals. Use a small flathead or special tool for spring or push-in types. Always match the tool to the terminal.

What should you do if a wire will not come out?

Try to find a release tab or lever. Wiggle the wire gently. Never pull hard. If the wire stays stuck, cut it close to the terminal. Prepare a new end before you reattach it.

Can you reuse wires after removing them from a terminal block?

You can reuse wires if they look clean and undamaged. Check for nicks or broken strands. Trim and strip the end if needed. Always use a new connector or ferrule for the best connection.

Is it safe to attach wire from battery terminal to a terminal block?

Yes, you can attach wire from battery terminal to a terminal block. Make sure the power is off. Match the wire size and terminal rating. Use the correct removal and attachment steps for safety.

Why should you label wires before removing them?

Labeling wires helps you remember where each one goes. You avoid mistakes when you put them back. Use tape or tags with clear writing. This step saves time and keeps your project organized.

See also

Pull type air circuit breaker AC690V

How to safely remove circuit breakers from distribution boxes

What Is a Terminal Block and How Does It Work

What You Should Know About Terminal Blocks and Their Other Names

How many types of wiring terminals are there?