Air circuit breakers (ACB) are the core components that ensure circuit safety, and their correct wiring directly affects the lifespan of electrical equipment and personal safety. This article combines national standards and practical experience to systematically analyze wiring specifications, common errors, and advanced techniques in home and industrial scenarios, helping you master professional level wiring skills.

What is an air circuit breaker?

Air circuit breaker (ACB) is a power system circuit control and protection appliance. It can automatically switch off the circuit to prevent equipment loss or fire because of faults such as overcurrent or short circuit. Air circuit breakers play a vital role in ensuring high voltage as well as low voltage power systems’ safety and stability.

Common air circuit breakers include 630 amperes, 1000 amperes, 1600 amperes, and can reach up to 6300 amperes.

Working principle of air circuit breaker

The working principle of air circuit breakers is based on changes in current. When the current exceeds the set safety threshold, the air circuit breaker will automatically disconnect the circuit, thereby avoiding further electrical accidents. Its core principles include the opening and closing of the main contacts, thermal and electromagnetic protection mechanisms, etc. All of these components work together to ensure the safety of the circuit.

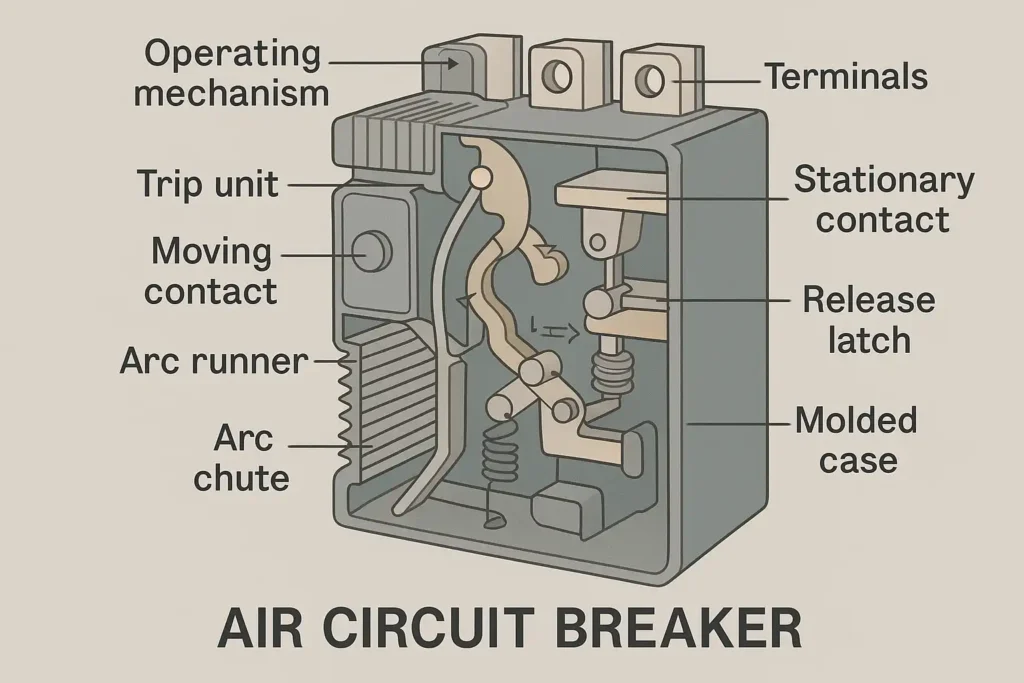

The structural composition of air circuit breakers

An air circuit breaker consists of multiple key components, including:

- Main contact: mainly responsible for connecting and disconnecting circuits.

- Auxiliary contacts: used for additional control and protection functions.

- Electromagnets and springs: mechanical devices used for quickly disconnecting circuits.

- Operating mechanism: manually or automatically start the air circuit breaker.

Preparation before wiring air circuit breakers

Home circuit: Single phase electricity (220V) needs to distinguish between live wire (L/red), neutral wire (N/blue), and ground wire (yellow green dual color). The ground wire is directly connected to the grounding bar, and it is prohibited to connect it to the circuit breaker

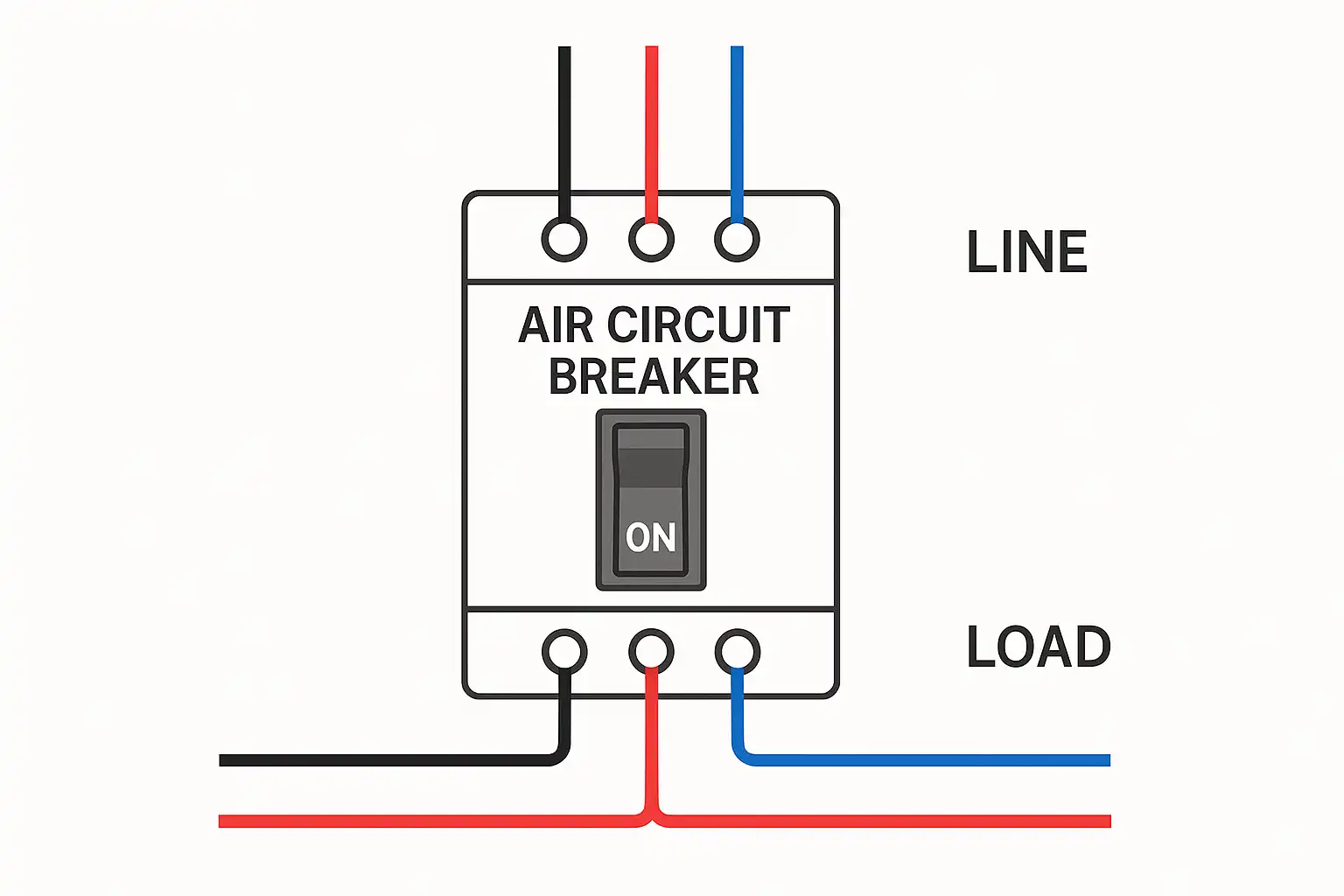

Industrial circuit: For three-phase electricity (380V), 3P or 4P circuit breakers should be selected to connect three live wires (yellow/green/red) and neutral wires respectively

Tool selection: Insulated screwdriver, crimping tool, torque wrench, wires need to match current specifications

Types of wiring methods for air circuit breakers

- single pole circuit breaker

Applicable scenarios: lighting circuits, low-power appliances (such as lamps).

Wiring method: Only connect the live wire (L), and directly connect the neutral wire (N) to the shared zero bar

- double pole circuit breaker

Applicable scenarios: socket circuits, 220V electrical appliances (such as air conditioners, water heaters).

Wiring rules: Follow the principle of “left zero, right fire”, but refer to the circuit breaker markings. Some models are marked with “L” as the live wire and “N” as the neutral wire

- 1P+N circuit breaker

Features: Combining the advantages of small single pole volume and dual pole protection function, the neutral wire is directly connected but the live wire is controlled

Attention to wiring: The neutral terminal (N) should be strictly matched to avoid reverse direction causing leakage protection failure

- Industrial three-phase circuit connection method

3P circuit breaker: Three live wires are connected to L1/L2/L3 terminals, and the equipment outputs directly without the need for neutral wires

4P circuit breaker: three fire and one zero wiring, suitable for 380V equipment that requires neutral wire (such as frequency converters)

Best practices for wiring air circuit breakers

For ensuring safe and reliable wiring of air circuit breakers, the following best practices need to be implemented:

1. Use proper tools and equipment

Ensure the use of proper tools to strip, cut, and crimp wires. This could avoid damaging wires or loose connections, hence preventing overheating or arcing.

2. Label wires and connections

Mark all connections and wires in a clear manner so that they are not confusing during installation and maintenance. This is particularly required in complex systems with more than one circuit and circuit breaker.

3. Check the tightness of the connection

Loose connections cause arcing, which can damage circuit breakers and increase the danger of fire. While installing, kindly ensure that all the terminal connections are tightened well.

4. Test the system

After wiring the air circuit breaker, the test is conducted in a sequence to verify that the system is operational. This includes insulation resistance testing, continuity testing, and trip testing of the circuit breaker.

Wiring rules that must be followed

- Polarity identification: Following the convention of “left zero, right fire”, but it is necessary to mark the circuit breaker (L/N) as the standard

- Wire processing: Bend multiple strands of wire into a “?” shape to increase contact area, fold and crimp the flexible wire, and prohibit parallel wiring

- Tightening standard: Use a torque screwdriver with a terminal torque of 2.5N · m to avoid overheating caused by poor contact

Air Circuit Breaker (ACB) Wiring Diagram Video

Common misconceptions and safety hazards

- Ground wire connected to circuit breaker

Incorrect operation: The ground wire was mistakenly connected to the circuit breaker terminal.

Risk: Electric shock caused by live ground wire and inability of circuit breaker to provide protection - Reverse connection of neutral wire and live wire

Consequence: The equipment casing may be charged, and the leakage protector may fail

Verification method: Use an electric pen to detect the output terminal of the circuit breaker and ensure that it is “left zero and right fire” - Ignore fastening force

Problem: The screws are not tightened, resulting in increased contact resistance and causing local overheating.

Solution: Use a torque screwdriver and operate according to standard torque

Conclusion

The correct wiring of air circuit breakers is the cornerstone of circuit safety. By standardizing the number of poles, avoiding common errors, and selecting models based on actual needs, the risk of fire and electric shock can be significantly reduced. If you have any questions, you can also leave a comment below, and we will reply and answer them as soon as possible. Before wiring, be sure to cut off the power and check it, and consult a professional electrician if necessary

Here is some information that you may have just become interested in:

Application and advantages of air circuit breakers

High quality air circuit breaker

Customizable intelligent air circuit breaker