You often see various types of automotive wiring terminals, including fork, ring, butt, bullet, lug, quick-connect, waterproof, Weather Pack, Metri-Pack, board-to-board, and wire-to-wire. You should check the wire gauge when selecting automotive wiring terminals. Pick the right material for the job, and consider moisture and temperature before you choose a terminal. Making informed choices keeps your connections safe and helps your car perform better. Both DIY car owners and mechanics need to know how to pick the best automotive wiring terminals to ensure they do a good job.

Key Takeaways

- Pick the correct automotive wiring terminal for the wire size. This helps make safe and strong connections.

- Think about what the terminal is made of and its coating. Good materials stop rust and help electricity move better.

- Choose terminals that fit the place they will be used. Use waterproof connectors in wet spots to keep your car’s wires safe.

- Look at the connections after you put them in. Make sure no wires are showing and the crimp is tight so it works well.

- Use a checklist when picking terminals. This helps you find the best terminal for your car’s needs.

Automotive Wiring Terminals Overview

What Are Wiring Terminals

Wiring terminals help connect wires in your car. They make sure wires stay together and electricity moves safely. These parts come in many shapes and sizes. Each one is made for a special job. For example, a ring terminal connects a wire to a bolt. A butt connector joins two wires together.

Here is a simple table that shows what wiring terminals do:

| Terminal Type | Main Function |

|---|---|

| Ring | Attach wire to a stud |

| Fork | Quick wire removal |

| Butt | Join two wires |

| Bullet | Fast disconnect |

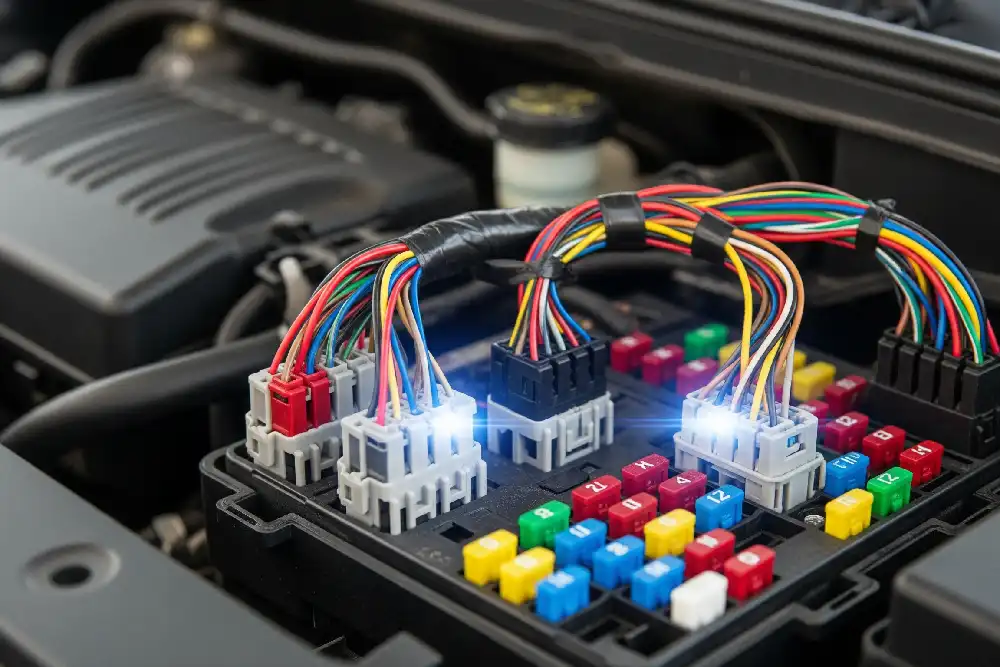

You can find these terminals all over your car. They are in the battery area, fuse box, and lights. You must use the right terminal for each job. This keeps your car working well.

Tip: Always use a terminal that fits your wire size. This stops loose wires and electrical trouble.

Why Terminal Selection Matters

Picking the right terminal makes your car safer. The right choice keeps wires from coming loose. It also blocks water and dirt from getting in. If you use the wrong terminal, your car may not work right.

Think about these reasons when you pick a terminal:

- You keep your car’s electronics safe.

- You stop short circuits and fires.

- You help your car’s electrical system work better.

Automotive wiring terminals are important for safety and performance. You should look at the type, size, and material of each terminal. Choosing carefully helps you avoid trouble and keeps your car running well.

Types of Automotive Wiring Terminals

Fork Terminals

- Fork terminals help you connect a wire to a screw fast. Their open end lets you slide them under a screw without taking it out. You see fork terminals in fuse boxes and relay panels. They are good for connections you might need to change.

Tip: Fork terminals make repairs quicker since you do not remove the whole screw.

Ring Terminals

- Ring terminals have a closed loop that fits over a stud or bolt. You use them when you want a strong connection that will not fall off. You see ring terminals on battery cables and grounding wires. The closed shape keeps the wire from coming loose.

Butt Connectors

Butt connectors join two wires together end-to-end. You use them to fix or make wire groups longer in your car. Put each wire in the connector and crimp it to hold tight. This keeps your car’s electrical parts working right and safe.

You use butt connectors for repairs, wire extensions, or to keep wires neat and safe inside the harness.

Bullet Connectors

- Bullet connectors have a round shape with a male and female end that snap together. You use them for quick connects and disconnects in small spaces. They are used in lighting circuits and speaker wires. The shape helps stop wires from pulling apart by accident.

Lug Terminals

- Lug terminals have a flat end with a hole for a bolt or screw. You use them for strong connections like battery cables or starter motors. They can handle lots of current and make a solid bond. You see lug terminals in engine bays and main power feeds.

Quick-Connect Terminals

- Quick-connect terminals let you attach and remove wires fast. You use them where you need to take parts out often. They are good for industrial control systems. You find them in automotive wiring harnesses for fast connections.

Note: Quick-connect terminals follow rules to make sure your car’s connections are safe and work well.

Waterproof Connectors

Waterproof connectors keep wires safe from water, dust, and dirt. You use them in wet places like engine areas or outside lights. These connectors have seals and locks to keep water out.

| IP Rating | Description |

|---|---|

| IP67 | Dust-tight; can go under water up to 1 meter for 30 minutes. |

| IP68 | Can go deeper under water for longer (check with maker). |

Pick waterproof connectors with the right IP rating for your job.

Weather Pack Connectors

- Weather Pack connectors are special waterproof connectors for tough places. You use them in engine bays, under cars, or where there is rain or mud. They have seals and locks to keep out water and dirt. You see them in GM cars and off-road vehicles.

Metri-Pack Connectors

- Metri-Pack connectors are small, sealed connectors in newer cars. You use them for sensors, lights, and control modules. They protect well from water and shaking. You find Metri-Pack connectors in many new cars and trucks.

Board-to-Board Connectors

- Board-to-board connectors link two printed circuit boards inside car electronics. You use them in engine control units, lighting systems, infotainment, and battery systems in electric cars. These connectors help send signals and power between modules.

Wire-to-Wire Connectors

- Wire-to-wire connectors join two or more wires in a harness. You use them to connect different parts of the car’s electrical system. They come in many shapes and sizes, some sealed and some not. You see wire-to-wire connectors in dashboards, doors, and lights.

Remember: Picking the right automotive wiring terminals for each job keeps your car safe, reliable, and easy to fix.

Terminal Uses and Features

Common Applications

Automotive wiring terminals are found all over your car. Each type does a special job. Blade terminals go in fuse boxes. These flat connectors make fast, safe connections. Pin terminals fit in electronic control units. They are small and carry signals between parts.

Ring terminals connect battery cables. They give a strong, safe bond. Spade terminals look like forks. You use them for switch panels. They are easy to remove for repairs. Bullet terminals snap together in motorcycle wires. They let you disconnect wires quickly.

Flag terminals fit in small dashboards. Their right-angle shape saves space. Fuse terminals work in fuse systems. They protect your car’s electrical circuits from harm.

Here is a table that shows where each terminal is used:

| Terminal Type | Description | Common Application |

|---|---|---|

| Blade Terminals | Flat, rectangular connectors | Fuse boxes |

| Pin Terminals | Cylindrical connectors | Electronic control units (ECUs) |

| Ring Terminals | Circular connectors that fit over a bolt | Battery cable connections |

| Spade Terminals | Fork-shaped connectors | Switch panels |

| Bullet Terminals | Rounded connectors that snap together | Motorcycle wiring systems |

| Flag Terminals | Right-angled connectors for tight spaces | Inside compact dashboards |

| Fuse Terminals | Integrated terminals used in fuse systems | Fuse systems |

Tip: Pick the right terminal for the job. This keeps your car safe and simple to fix.

Distinguishing Features

You can tell terminals apart by their shape and size. Blade terminals are flat. You slide them into slots. Pin terminals are round and fit in small holes. Ring terminals have a closed loop. You bolt them down for a tight hold.

Spade terminals look like forks. You slip them under screws for quick changes. Bullet terminals snap together. They are good for fast disconnects. Flag terminals bend at a right angle. They fit in tight places where straight ones cannot go.

Fuse terminals have a connector and a fuse. They protect circuits from too much power. Waterproof terminals have seals. You use them in wet spots to keep water out.

Note: Look for insulation, sealing, and locking tabs. These features help you pick the best terminal for each part of your car.

Selecting Automotive Wiring Terminals

Wire Gauge Compatibility

You must use the right terminal for your wire size. Most automotive wiring terminals fit wires from 10 AWG to 20 AWG. If you pick the wrong size, you can have trouble. The wrong size can make resistance go up and voltage drop. If the fit is too loose or tight, wires can get hot. Bad matches might make your car’s wires stop working.

Tip: Always look at the wire gauge before picking a terminal. This helps keep your wires safe and working well.

Material and Plating

The material and plating of a terminal help it last longer. Copper is used a lot because it lets electricity flow well. But copper needs a cover to stop rust. Plating like tin, gold, or nickel keeps rust away and helps electricity move better.

| Material | Plating Options | Impact on Corrosion Resistance |

|---|---|---|

| Copper | Tin, Gold, Palladium | Needs plating to prevent oxidation and contact resistance |

| Nickel | N/A | Provides wear resistance and prevents copper migration |

| Copper | Silver, Gold, Tin | Improves corrosion and oxidation resistance |

| Copper Alloys | Silver, Gold, Tin | Enhances anti-rust properties |

Tin is cheap and works well, but it can wear out over time. Gold is great for electricity, but it needs nickel to stop copper from moving. Nickel makes the terminal strong and helps with electricity.

Note: Pick the best material and plating for where you use the terminal. This helps your terminals last longer.

Environmental Factors

Think about where you will put the terminal. Water, dirt, and heat can hurt your wires. Use waterproof or sealed terminals in wet or dirty spots, like under the hood or car. High heat can make some terminals weak, so use ones made for hot places.

- Use sealed connectors outside or in the engine.

- Pick terminals that can handle high heat for hot areas.

- Do not use bare terminals where there is lots of water or salt.

Callout: The right terminal keeps your wires safe from rust and breaking.

Electrical Requirements

You need to know how much power your terminal will carry. Most cars use 12V, but some use 24V or 48V, like electric cars. Make sure your terminal can handle the most current without getting too hot.

- Check the terminal’s current rating before using it.

- Lower the rating if wires are close together or in hot spots.

- For data wires, use shielded or twisted-pair terminals to keep signals clear.

Tip: Never use a terminal that cannot handle your car’s voltage or current.

Application Needs

Think about what you want the terminal to do. Some jobs need quick disconnects, others need strong, lasting connections. Use ring terminals for battery cables. Use quick-connects for parts you take out a lot. In small spaces, flag or right-angle terminals save room.

- Pick terminals that fit your repair or upgrade.

- Use locking or sealed types for important systems.

- Choose easy-to-remove types for parts you fix often.

Selection Checklist

Check these things before you buy or use a terminal:

- Match the wire gauge to the terminal.

- Pick the right material and plating for your area.

- Make sure the terminal fits your voltage and current.

- Choose a terminal that fits your space and job.

- Use sealed or waterproof types in wet or dirty places.

- Make sure the terminal is safe for your car.

✅ Use this checklist to help you pick the best automotive wiring terminals for any job.

Installation and Quality Tips

Crimping and Connection

You need to make strong connections when you install automotive wiring terminals. Crimping is the most common way to attach a terminal to a wire. You use a crimping tool to squeeze the metal terminal onto the wire. This holds the wire tight and keeps electricity flowing.

Steps for Proper Crimping:

- Strip the wire. Remove just enough insulation so the bare wire fits inside the terminal.

- Insert the wire into the terminal barrel. Make sure all strands go inside.

- Use the correct crimping tool. Match the tool to the terminal type and wire gauge.

- Squeeze the tool firmly. You should feel the terminal grip the wire.

- Tug the wire gently. The wire should not pull out.

Tip: Always use a dedicated crimping tool. Pliers or makeshift tools can cause weak connections.

You can also use solder for extra strength, but crimping alone works well for most jobs. For waterproof terminals, make sure the seal fits snugly around the wire.

Inspecting for Reliability

After you finish the connection, you need to check your work. Reliable connections keep your car safe and prevent electrical problems.

What to Check:

- Look for exposed wires. No copper should stick out from the terminal.

- Check the crimp. The terminal should not wiggle or spin on the wire.

- Inspect insulation. The wire’s insulation should touch the terminal’s insulation sleeve.

- Test the connection. Gently pull on the wire and terminal. They should stay together.

| Inspection Point | What to Look For |

|---|---|

| Exposed Wire | None visible |

| Crimp Tightness | No movement or looseness |

| Insulation Coverage | Full coverage, no gaps |

| Seal Fit (if needed) | Snug, no gaps for water to enter |

✅ Careful inspection helps you catch mistakes before they cause trouble. Always double-check your work for the best results.

You have learned about the main types of automotive wiring terminals. You also know how to pick the right one for your car. Always look at the wire size before you choose a terminal. Think about what the terminal is made of and where you will use it. Here is a table to help you remember what to check:

| Criteria | Description |

|---|---|

| Current Rating | Make sure it works safely in your car. |

| Environmental Resilience | Pick terminals that can handle heat and shaking. |

| Material Properties | Choose the best metal for your job and money. |

| Compliance with Standards | Check if the terminal meets SAE rules for safety. |

Use the checklist and tips in this guide to make safe and strong wire connections. If you want more help, look at trusted car repair websites or guides from the maker.

FAQ

What is the best way to choose the right terminal for my car?

You should match the terminal to your wire gauge. Check the material and make sure it fits your car’s needs. Use the checklist in this guide to help you pick the safest option.

Can I reuse automotive wiring terminals?

You should not reuse most terminals. Old terminals can get weak or damaged. Always use new terminals for strong and safe connections.

How do I know if my connection is waterproof?

Look for seals or gaskets on the connector. Check the IP rating in the product details. Waterproof connectors keep water out and protect your wires.

What tools do I need to install wiring terminals?

You need a wire stripper and a crimping tool. Some jobs may need a soldering iron. Always use the right tool for your terminal type.

Why do some terminals have colored insulation?

Colored insulation shows the wire gauge size. It helps you pick the right terminal quickly. For example, red fits small wires, blue fits medium, and yellow fits large wires.

See also

How to Install Wiring Terminals and Terminal Blocks Step by Step

Why Choose Customized Terminal Blocks for Unique Electrical Needs

IP65 waterproof car charger for electric vehicles

What Happens If Your Electric Vehicle Charger Lacks Surge Protection

Intelligent WIFI wireless electric car charger