Automatic-transfer-switch-solution.webp)

Automatic transfer switch manufacturer

ONESTOP is a leading manufacturer of automatic transfer switches in the market. With over 19 years of experience in the electrical industry, we offer high-quality products at the most competitive prices.

WHY CHOOSE US

Production technology

Customization and OEM/ODM

High performance-price ratio

Long term partnership

Automatic transfer switch products

If you need to learn more about product types or customized solutions, please feel free to contact us at any time.

Provide economically sustainable power solutions

Our electrical solutions have served over 50 countries and regions worldwide.

Long term cooperation with over 300 manufacturing companies, including globally renowned industrial brands

Over 800 industrial projects have been delivered, of which 60% are customized solutions

Key Features of Automatic Transfer Switches

Automatic Transfer Switches (ATS) are designed to seamlessly switch between primary and backup power sources, ensuring your electrical systems remain operational during outages. These systems are essential for both residential and commercial applications, offering peace of mind and reliability. They help prevent costly downtime and provide immediate power supply without manual intervention. Explore the following key features that make ATS a smart investment.

Automatic-transfer-switch-in-work.webp)

Seamless Power Transfer

Automatic Transfer Switches ensure a seamless transition between power sources, keeping your devices running without interruption.

- Instantaneous Switching

- No Manual Operation

- Eliminates Downtime

Automatic Monitoring

ATS units continuously monitor the primary power supply and automatically switch to backup power when needed, ensuring reliability.

- Real-time Monitoring

- Automatic Switching

- Reliability Checks

Automatic-transfer-switch-in-operation-1024x683.png)

Durable Construction

Designed to withstand demanding conditions, Automatic Transfer Switches are built to last and provide dependable service.

- Weather-resistant Casing

- Robust Components

- Long Lifespan

Flexible Installation Options

Automatic Transfer Switches offer flexible installation choices, catering to various setups in residential and commercial settings.

- Wall Mount

- Tabletop

- Integrated with Existing Systems

The advantages of our product

Accurate automatic switching

ATS can automatically detect power supply abnormalities and switch to backup power supply during power outages, ensuring uninterrupted operation of equipment.

Independently completed

Independently completing the switch reduces the possibility of human negligence, especially in emergency situations, allowing for quick response

Improve reliability

ATS can significantly improve the reliability of power systems, avoiding production or service disruptions caused by power outages, and is suitable for critical facilities such as hospitals and data centers.

improve security

It can reduce safety risks during power switching, especially in environments with unstable power supply, and avoid electrical accidents that may occur during manual switching

Can be monitored and managed

ATS systems are usually equipped with remote monitoring functions, allowing administrators to view the status and switching of the power system in real time, facilitating management and maintenance.

Adapt to various load requirements

ATS can be used in conjunction with different types of backup power sources (such as diesel generators, UPS, etc.) to meet the power needs of different loads and equipment.

What Our Customers Say About Automatic Transfer Switches

See how Automatic Transfer Switches have transformed power management for our customers.

Your trusted electrical equipment supplier

♥Wide selection

♥OEM Quality

♥100% Satisfaction Guarantee

Looking forward to working with you

FAQ

Find answers to common questions about Automatic Transfer Switches and their applications.

What is an Automatic Transfer Switch?

An Automatic Transfer Switch (ATS) is a device that automatically switches the electricalload of a building from the main power source to a backup power source during anoutage.

How does an Automatic Transfer Switch work?

The ATS continuously monitors the power supply and switches automatically to backupwhen a failure is detected, providing a seamless power transition.

Why should linvest in an Automatic Transfer Switch?

Investing in an ATS ensures your power remains uninterrupted during outages, protectingyour systems and reducing downtime.

What are the applications of Automatic Transfer Switches?

ATS can be used in residential, commercial, and industrial settings, making them versatile

for many power needs.

Are Automatic Transfer Switches easy to maintain?

Yes, most Automatic Transfer Switches are designed for easy maintenance, requiring

minimal intervention.

Can Automatic Transfer Switches be customized?

Absolutely! Many Automatic Transfer Switches come with customizable options to fitindividual power needs.

What safety features do Automatic Transfer Switches have?

Automatic Transfer Switches come with numerous safety features such as overloadprotection and backfeed prevention.

How do l choose the right Automatic Transfer Switch?

Consider your power needs, installation space, and whether you prefer manual orautomatic switching when selecting an ATS.

What is the lifespan of an Automatic Transfer Switch?

With proper maintenance, Automatic Transfer Switches can last many years, providingreliable service.

Where can l buy an Automatic Transfer Switch?

You can purchase Automatic Transfer Switches from electrical supply stores or onlineretailers specializing in power equipment.

Understand the automatic transfer switch

Table of Contents

Automatic transfer switch is a device to transfer power supply automatically during a power outage. Ranging from households to commercial and industrial premises, ATS has a significant role to play. It not only permits smooth operation of equipment during a power failure, but also reduces manual handling and increases the power system’s dependability and security.

This paper will present an in-depth overview of the operation principle, types, application areas, and choosing proper ATS equipment for automatic transfer switches.

What is an automatic transfer switch

Automatic transfer switch is an electric device whose major role is to automatically transfer to the alternative power source when there is failure in the main power supply. The main purpose of the switch is to avoid shutdown of equipment or safety hazard when there is a loss of power. It is usually used between main power supply, UPS (uninterruptible power supply), and generator sets.

Analysis of the principle of automatic transfer switch

1.Power monitoring and fault detection

ATS continuously monitors the status of the main power supply. If voltage drop, frequency drift, phase loss, or complete power failure is detected, the controller will call the switching program. For example, in the event of a main power failure, ATS uses a 1-second delay (adjustable) to confirm anomalies and avoid false alarms

2.Start-up and preparation for backup power

For a generator backup power source, ATS sends a start command, and the generator transfers when it reaches a stable state (voltage and frequency requirements are achieved). This is done typically with a 3-second delay to prevent improper start-ups of the generator

3.Switching between Execution and Security Assurance

Mechanical interlocking: ensures that two power sources cannot be connected simultaneously through mechanical structure, avoiding the risk of short circuit

Switching method:

- Open transition: After disconnecting the main power supply, briefly cut off the power and then close the backup power supply. Suitable for ordinary loads, the switching time is about 100ms-2 seconds

- Closed transition (such as STS static switch): using electronic devices to achieve “closing first and then closing”, with a switching time of ≤ 8ms, suitable for IT equipment sensitive to power outages

- Intermediate position delay: For high inductive loads (such as electric motors), ATS switches to the intermediate position and stays for 0.5-1 second, waiting for the back electromotive force to decay before completing the switch to avoid current surges

4.Main power restoration and switching back

After the main power supply returns to normal, ATS confirms stability after a preset delay (such as a 30 minute cooling cycle), automatically switches back to the main power supply, and shuts down the backup generator

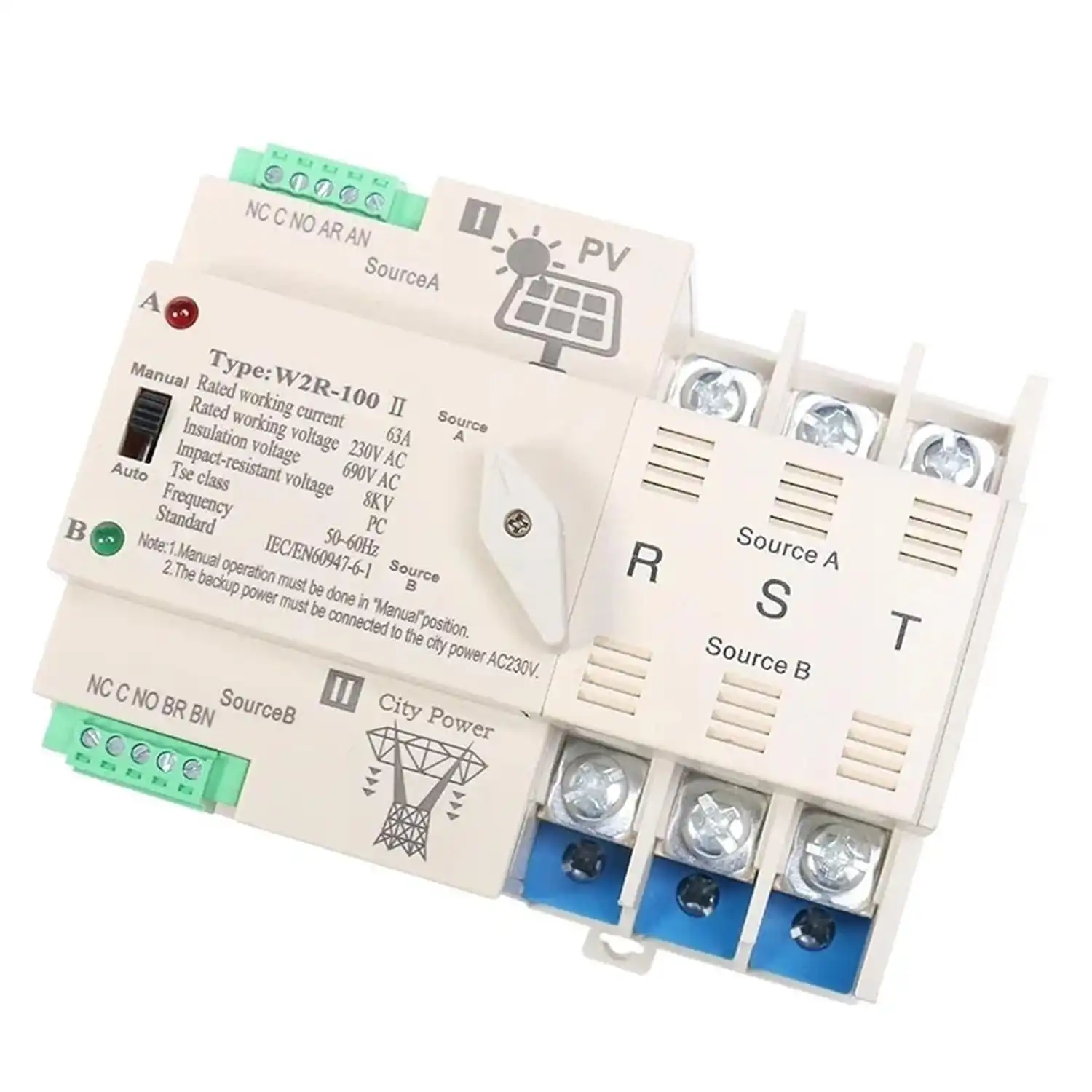

Basic structure of automatic transfer switch

Types of automatic transfer switches

Application scenarios of automatic transfer switch

1. Data Center

The data center needs 24 hours of continuous power supply, and ATS automatically transfers to backup power to avoid data loss or equipment damage, thereby keeping the business uninterrupted.

2. Hospitals and medical facilities

The hospital’s life support system, monitoring equipment, etc. need to be functional. Any power supply interruption can be hazardous to human life, so ATS is an essential component of hospital power systems.

3. Commercial buildings

Commercial buildings consume extremely high voltage of electricity, such as lights, elevators, and a great deal of electrical appliances. ATS will switch over to the alternate source of power in case of failure of the main source of power so that there is no interruption due to power cut.

4. Industrial usage

Industrial plants and machinery need high power stability, particularly while conducting production. The application of ATS prevents extended downtime, thus increasing the production rate.

How to choose the appropriate automatic transfer switch?

Introduction-to-Automatic-Transfer-Switch-Function.webp)

Maintenance and upkeep of automatic transfer switch

Regularly check the power contacts: ensure that the contacts are not corroded or loose.

Test system function: Regularly simulate power faults and check whether ATS can switch power supply normally.

Cleaning equipment: Avoid the accumulation of dust and dirt, which may affect the normal operation of the equipment.

Check battery: For ATS with batteries, it is necessary to regularly check the battery level and replace aging batteries.

Automatic-transfer-switch-products-1024x1024.webp)

Automatic-transfer-switch-products.webp)

Latest-automatic-transfer-switch.webp)

Latest-automatic-transfer-switch.webp)